A Higher Standard of Precision

Mitsubishi Electric’s approach to elevator and escalator design and manufacturing mandates that the highest levels of engineering precision go into every aspect of our products. Applying IT-based tools that aid in developing artificial intelligence technology helps to provide an efficient and energy-saving ride.

Our company consistently plays a leading role in the invention of products with improved performance and increased user convenience. This approach has made it possible for Mitsubishi Electric to become a pioneer of innovation and an industry trend-setter — developing game-changing products for architects, general contractors, building owners and project managers to have more creativity and flexibility in creating memorable public spaces.

Some of our leading innovations:

World Record Setter*

- World's Fastest Down Direction Elevator (time period 2016-2019) — at a speed at 2,460 feet per minute – Yokohama Landmark Tower in Japan

- World's Tallest Elevator — Also located in the Shanghai Center, the world's tallest elevator has a rise of over 1,897 feet.

- World's Fastest Double-Deck Elevators - The third record holder in the Shanghai Center, our double-deck elevators travel at approximately 1,968 feet per minute.

* Mitsubishi Electric research as of October 2019

AI Supervisory Control, Expert System and Fuzzy Logic

Mitsubishi Electric's application of breakthrough artificial intelligence technology to elevator control has resulted in improved operational efficiency and new functions that can be configured to suit a variety of building types —including hospitality, apartments & condominiums, commercial office buildings and more. Pioneered by Mitsubishi, this technology has been around for over 30 years.

An intelligent "Expert System" comprises the brains behind AI Supervisory Control — so-named in that it incorporates the practical knowledge and experience of actual elevator group control experts to form a knowledge database stored inside the system's memory. Our elevator control system maximizes the operational effectiveness of each car by drawing from the knowledge database and applying decision rules to monitor and analyze traffic conditions.

Our elevator group control systems can make decisions using fragmentary and fuzzy logic intelligence concepts. Using its built-in "intelligence" and "common sense," the system can determine whether potential car assignments will result in longer waiting times for future calls or contribute to elevator congestion. This assessment results in improved performance and operational efficiency, which is one of the key points builders are looking for with their escaltor and elevator installation.

Spiral Escalators

Mitsubishi Electric is the only company in the world to develop and manufacture a commercial-grade spiral (curved) escalator — with our first U.S. installation occurring more than 28 years ago and still running smoothly, quietly and safely today.

We innovated the “centralized motion method” in which the central point moves in stages based on the angle of the incline. A special chain capable of supporting a wide variety of angles required for the spiral orbit moves the steps. Horizontal rollers are installed on the outer-side of the chain, enabling the structure to manage the inward force generated by the arching configuration. This enables the escalator steps to move along the fixed orbital plane with high accuracy. With these innovations, we are providing spiral escalators to architects and building owners — allowing them the artistic ability to provide a three-dimensional perspective and expansive panoramic view to the users.

Elevator Research Tower – SOLAÉ

Imagine building a skyscraper solely for the purpose of testing new elevator products. Mitsubishi Electric didn’t just imagine it, we actually built it. With a height equivalent to a 40-story building, SOLAÉ's role in elevator development includes conducting safety, comfort, ride and sound tests that cannot be done by a computer to ensure our products’ precision and quality. With the demand for more high-speed, high-capacity elevators rising exponentially, Mitsubishi Electric’s SOLAÉ testing tower contributes to the development of high-quality, reliable elevators that fulfill these demands. Data gathered at SOLAÉ is directly funneled into future elevator development — ensuring that our company remains at the forefront of technological advancement and providing builders with peace of mind, knowing what lengths Mitsubishi goes to in order to test our elevators and escalators.

Airflow Analysis Technology

The large volume of air pushed by an elevator traveling at high speed can create unpleasant noise inside the passenger car. Two high-speed elevators passing each other in a common hoistway create forces that need to be fully understood before they can be harnessed into a quieter and more energy-efficient elevator installation. Mitsubishi Electric's analysis technology displays a visual demonstration of vector distribution of airflow and pressure on car surfaces — which helps answer questions about performance and ensures a higher quality installation.

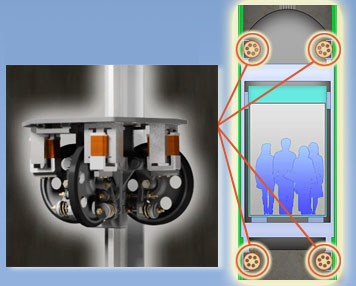

Active Roller Guide

The amount of lateral vibration generated by high-speed elevator cars is tremendous. An innovation in the industry, Mitsubishi Electric's Active Roller Guide technology greatly reduces that vibration — using an accelerometer that detects car vibration during operation and actuators that cancel the vibration through a controlled electromagnetic force. Mitsubishi Electric Active Roller Guides ensure a more comfortable ride than elevators that use conventional roller guides.

Destination Controls (DOAS®)

The Destination Oriented Allocation System (DOAS®) is a unique allocation system that provides passengers with the fastest and least crowded route to their destinations. When a passenger enters a destination floor number on a hall operating panel, the best car is automatically allocated to the passenger and the elevator number is displayed on the panel. The passenger goes to the assigned car, gets in and does not need to push any more buttons — as the floor destination has already been programmed into the control program.

Motor Drive Mix

Mitsubishi Electric's Motor Drive Mix technology shortens waiting times during congested periods by increasing elevator acceleration between floors. The elevator's acceleration and deceleration rates are adjusted according to car load and traffic conditions to maximize driving system efficiency.

Green Technologies

Mitsubishi Electric strives to be green in all of our business activities, including our elevator and escalator products. From regenerative drives to LED lighting, we are focused on reducing the carbon footprint of our products. An introduction to the environmental initiatives implemented throughout all our business activities — from product development to maintenance and modernization — is provided in our brochure: