Mitsubishi Electric machine-room-less elevator quality is second to none, and our Diamond-Trac® gearless elevator provides technological advances that deliver a world-class ride, maximum MRL life cycle and exceptional reliability — with an average of less than one callback per elevator per year with our maintenance plans. We also provide monitoring services for our machine-room-less elevators.

Our Destination Dispatch System

Our ΣAI-2200C Destination Dispatch System uses intuitive operation to offer an efficient, comfortable ride. The Destination Oriented Allocation System (DOAS®) enables passengers to register their destination floor before entering the elevator by using a hall operating panel. With the latest advancements in fuzzy-logic, the system selects the optimal car to respond based on factors such as waiting time, travel time, current car occupancy and energy consumption. Flexible car allocation helps reduce congestion and minimizes the risk of passenger irritability.

READY CONNECT® Network Communication Protocol Gateway

READY CONNECT® is a network communication device that allows Mitsubishi Electric Diamond-Trac® and Diamond HS™ passenger elevator systems to communicate and connect with other building systems, acting as an interpreter. Historically, elevator systems have been relatively isolated and difficult to integrate with other building systems for monitoring and control. Mitsubishi Electric’s READY CONNECT® network communication protocol gateway, however, opens the doors to the next level of connectivity with the ability to speak to multiple systems, including HVAC, security and user information systems, concierge desk assistant bots, parking garages and more.

Introducing our PureRide® Vertical Transportation Solutions

PureRide® Touchless Control

This simple, no-touch product allows users to call an elevator and designate a destination floor by placing a hand or finger over a sensor without the need to touch at all.

Elevator Call System via Smartphone

Our exclusive smartphone application is designed to offer even more convenient access to elevators equipped with the DOAS Integrated with Security System. This intuitive and user-friendly app increases mobility and helps add value to the building. With the ID Card Call function, passengers can request an elevator from the lobby to their destination floor before entering building security. After authenticating at security via ID card, passengers confirm their assigned elevator once inside the building. With the Smartphone Call function, passengers already in the building can select their departure and destination floors when requesting an elevator. With both functions, the smartphone displays the elevator assigned to the passenger, shows its current status, and uses push notifications to alert the passenger as the elevator car approaches. Passengers can also easily request a wheelchair accessible elevator, when needed.

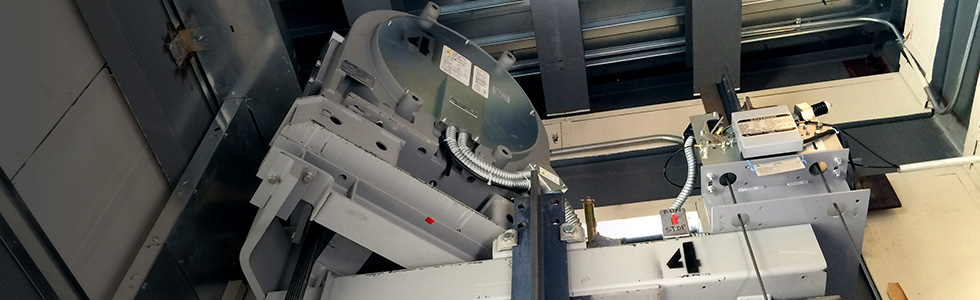

How MRL elevators work

Machine-room-less elevators utilize a gearless traction machine located in the hoistway. The use of a counterweight assists the machine in turning the elevator sheave, which moves the cab through the hoistway. Most commonly seen in hotels, apartments, mixed-use buildings and commercial offices, MRL elevators can handle 2 to 25 stops (with a typical capacity of 2,100 to 5,000 lbs.) and feature flexible design. Large capacities (4,000 lbs. and above) can accommodate heavier cab finishes.

Request a Quote Download Drawings

Downloads

M’s BRIDGE™

"M’s BRIDGE™" connects your elevators with a service called "Predictive Maintenance". We combine optimal maintenance technologies accumulated and improved over many years with the latest technologies.

The EZ-Assist System

Use our convenient online tool to help efficiently plan an elevator installation project. The free service includes useful tools for calculating passenger traffic, creating layout drawings, and applying elevator specifications.

Diamond-Trac® Dimensions and Specifications (Passenger)

| Opening | Front Opening | Front Opening | Front Opening | Front Opening |

|---|---|---|---|---|

| Capacity (lbs.) | 2000/Passenger | 2500/Passenger | 3000/Passenger | 3500/Passenger |

| Speed (fpm) | 200, 350, 400, 500 | 200, 350, 400, 500 | 200, 350, 400, 500 | 200, 350, 400, 500 |

| Hoistway (w x d) | 7’ 6” x 6’ - 11” | 8’ 6” x 6’ 11” | 8’ 6” x 7’ 4” | 8’ 6” x 8’ |

| Platform (w x d) | 6’ x 5’ 1” | 7’ x 5’ 1” | 7’ x 5’ 6” | 7’ x 6’ 2” |

| Inside Clear | 5’ 8” x 4’ 3 ¾” | 6’ 8” x 4’ 3 ¾” | 6’ 8” x 4’ 8 ¾” | 6’ 8” x 5’ 4 ¾” |

| Door Type | SS | SS, CO | SS, CO | SS, CO |

| Entrance Width | 3’ | 3’ 6” | 3’ 6” | 3’ 6” |

| Pit (200 fpm) | 5’ 5 ½” | 5’ 5 ½” | 5’ 5 ½” | 5’ 5 ½” |

| Pit (350 fpm) | 5’ 11 ½” | 5’ 11 ½” | 5’ 11 ½” | 5’ 11 ½” |

| Pit (400 fpm) | 6’ 3” | 6’ 3” | 6’ 3” | 6’ 3” |

| Pit (500 fpm) | 7’ 5” | 7’ 5” | 7’ 5” | 7’ 5” |

| Overhead (200 fpm)* | 14’ 3” | 14’ 3” | 14’ 3” | 14’ 3” |

| Overhead (350 fpm)* | 14’ 6” | 14’ 6” | 14’ 6” | 14’ 6” |

| Overhead (400 fpm)* | 15’ 5” | 15’ 5” | 15’ 5” | 15’ 5” |

| Overhead (500 fpm)* | 16’ 3” | 16’ 3” | 16’ 3” | 16’ 3” |

| Maximum Travel (200 fpm) | 75’ | 75’ | 75’ | 75’ |

| Maximum Travel (350 fpm) | 98’ 5” | 98’ 5” | 98’ 5” | 98’ 5” |

| Maximum Travel (400/500 fpm) | 262’ 5” | 262’ 5” | 262’ 5” | 262’ 5” |

| Opening | Front Opening | Front Opening | Front & Rear | Front & Rear |

|---|---|---|---|---|

| Capacity (lbs.) | 3500/Passenger (Heavy Duty) | 4000/Passenger | 3500/Passenger | 4000/Passenger |

| Speed (fpm) | 200, 350, 400, 500 | 200, 350, 400, 500 | 200, 350, 400, 500 | 200, 350, 400, 500 |

| Hoistway (w x d) | 8’ 7” x 8’ | 9’ 7” x 8’ | 9’ 7” x 7’ 11 1⁄4 ” | 10’ 9” x 8’ |

| Platform (w x d) | 7’ x 6’ 2” | 8’ x 6’ 2” | 7’ x 6’ 10 11⁄16” | 7’ 9” x 6’ 11” |

| Inside Clear | 6’ 8” x 5’ 4 3⁄4 ” | 7’ 8” x 5’ 4 ¾” | 6’ 8” x 5’ 8 3⁄16 ” | 7’ 5” x 5’ 9” |

| Door Type | SS, CO | CO | SS, CO | CO |

| Entrance Width | 3’ 6” | 4’ | 3’ 6” | 4’ |

| Pit (200 fpm) | 5’ 8” | 5’ 8” | 5’ 5 ½” | 6’ 4” |

| Pit (350 fpm) | 6’ 5” | 6’ 5” | 5’ 11 ½” | 6’ 7” |

| Pit (400 fpm) | 6’ 10” | 6’ 10” | 6’ 5” | 7’ 9” |

| Pit (500 fpm) | 7’ 7” | 7’ 7” | 7’ 6 ½” | 8’ 9” |

| Overhead (200 fpm)* | 15’ 1” | 15’ 1” | 14’ 3” | 16’ 10” |

| Overhead (350 fpm)* | 15’ 9” | 15’ 9” | 14’ 6” | 17’ 8” |

| Overhead (400 fpm)* | 16’ 2” | 16’ 2” | 15’ 5” | 18’ |

| Overhead (500 fpm)* | 16’ 11” | 16’ 11” | 16’ 3” | 18’ 8” |

| Maximum Travel (200 fpm) | 196’ | 196’ 10” | 75’ | 195’ |

| Maximum Travel (350 fpm) | 295’ | 295’ | 98’ 5” | 262’ |

| Maximum Travel (400/500 fpm) | 295’ | 295’ | 262’ 5” | 295’ |

*Note: The contents of these tables are standard specifications based on an 8 ft. cab height, please consult your local sales office for other specifications.

Diamond-Trac® Dimensions and Specifications (Service)

| Opening | Front Opening | Front Opening | Front & Rear | Front Opening | Front & Rear |

|---|---|---|---|---|---|

| Capacity (lbs.) | 4000/Service | 4500/Service | 4500/Service | 5000/Service | 5000/Service |

| Speed (fpm) | 200, 350, 400 | 200, 350, 400 | 200, 350, 400 | 200, 350 | 200, 350 |

| Hoistway (w x d) | 8’ 7 ½” x 9’ 1” | 8’ 7 ½” x 9’ 8” | 8’ 7 ½” x 10’ 8 ¾” | 8’ 7 ½” x 10’ 3” | 8’ 7 ½” x 11’ 3 ¾” |

| Platform (w x d) | 6’ x 8’ 3” | 6’ x 8’ 10” | 6’ x 9’ 5 ⅜ ” | 6’ x 9’ 5” | 6’ x 10 ⅜ ’ |

| Inside Clear | 5’ 8” x 7’ 4 ¼” | 5’ 8” x 7’ 11 ¼” | 5’ 8” x 8’ | 5’ 8” x 8’ 6 ¼” | 5’ 8” x 8’ 7” |

| Door Type | 2S | 2S | 2S | 2S | 2S |

| Entrance Width | 4’ | 4’ | 4’ | 4’ | 4’ |

| Pit (200 fpm) | 5’ 8” | 5’ 8” | 5’ 8” | 6’ 1” | 6’ 1” |

| Pit (350 fpm) | 6’ 1” | 6’ 1” | 6’ 1” | 6’ 2” | 6’ 2” |

| Pit (400 fpm) | 6’ 10” | 6’ 10” | 6’ 10” | n/a | n/a |

| Overhead (200 fpm)* | 15’ 1” | 15’ 1” | 15’ 2” | 15’ 1” | 15’ 2” |

| Overhead (350 fpm)* | 15’ 5” | 15’ - 5” | 15’ 10” | 15’ 5” | 15’ 10” |

| Overhead (400 fpm)* | 16’ 2” | 16’ - 2” | 16’ 2” | n/a | n/a |

| Max. Travel (250/350 fpm) | 196’ 10” | 196’ 10” | 196’ 10” | 196’ 10” | 196’ 10” |

| Max. Travel (400 fpm) | 295’ | 295’ | 295’ | n/a | n/a |

| Max. Bracket Span (15 lbs Rails) | 9’ 10” | 10’ | 10’ | 8’ 8” | 8’ 8” |

| Max. Bracket Span (18.5 lbs Rails) | 12’ 7” | 12’ 11” | 12’ 11” | 11’ 7” | 11’ 7” |

| Opening | Front Opening | Front & Rear |

|---|---|---|

| Capacity (lbs.) | 5000/Service (Wide) | 5000/Service (Wide) |

| Speed (fpm) | 200, 350 | 200, 350 |

| Hoistway (w x d) | 8’ 9 ½” x 10’ 1” | 8’ 9 ½” x 11’ 1 ¾” |

| Platform (w x d) | 6’ 2” x 9’ 3” | 6’ 2” x 9’ 10 ⅜” |

| Inside Clear | 5’ 10” x 8’ 4 ¼” | 5’ 10” x 8’ 5” |

| Door Type | 2S | 2S |

| Entrance Width | 4’ 6” | 4’ 6” |

| Pit (200 fpm) | 6’ 1” | 6’ 1” |

| Pit (350 fpm) | 6’ 2” | 6’ 2” |

| Pit (400 fpm) | n/a | n/a |

| Overhead (200 fpm)* | 15’ 1” | 15’ 2” |

| Overhead (350 fpm)* | 15’ 5” | 15’ 10” |

| Overhead (400 fpm)* | n/a | n/a |

| Max. Travel (200/350 fpm) | 196’ 10” | 196’ 10” |

| Max. Travel (400 fpm) | n/a | n/a |

| Max. Bracket Span (15 lbs Rails) | 8’ 8” | 8’ 8” |

| Max. Bracket Span (18.5 lbs Rails) | 11’ 7” | 11’ 7” |

*Note: For travel or stops outside of these ranges, please consult your local Mitsubishi Electric sales office.

Note: 5000 lbs service cars are also available with a 4' - 6' door width.

Passenger - One Car - Without Counterweight Safety

- SS = Single Side Opening

- CO = Center Opening

- Note: Counterweight safeties are required for buildings with occupied space beneath the elevator pit.

| Capacity (lbs.) / Speed (fpm) | Front Door Type | Front / Rear Door Type |

|---|---|---|

| 2000/200 | Not Available |

|

| 2000/350 | Not Available |

|

| 2500/200 | Not Available |

|

| 2500/350 | Not Available |

|

| 2500/400 (M1U) | Not Available |

|

| 2500/500 (M1U) | Not Available |

|

| 3000/200 | Not Available |

|

| 3000/350 | Not Available |

|

| 3000/400 (M1U) | Not Available |

|

| 3000/500 (M1U) | Not Available |

|

| 3500/200 | ||

| 3500/350 | ||

| 3500/400 (M1U) | ||

| 3500/500 (M1U) | ||

| 4000/200 | Not Available |

|

| 4000/350 | Not Available |

|

| 4000/400 | Available Upon Special Request |

|

| 4000/500 | Available Upon Special Request |

Passenger - One Car - With Counterweight Safety

- SS = Single Side Opening

- CO = Center Opening

- Note: Counterweight safeties are required for buildings with occupied space beneath the elevator pit.

| Capacity (lbs.) / Speed (fpm) | Front Door Type | Front / Rear Door Type |

|---|---|---|

| 2000/200 | Not Available |

|

| 2000/350 | Not Available |

|

| 2500/200 | Not Available |

|

| 2500/350 | Not Available |

|

| 2500/400 (M1U) | Not Available |

|

| 2500/500 (M1U) | Not Available |

|

| 3000/200 | Not Available |

|

| 3000/350 | Not Available |

|

| 3000/400 (M1U) | Not Available |

|

| 3000/500 (M1U) | Not Available |

|

| 3500/200 | ||

| 3500/350 | ||

| 3500/400 (M1U) | ||

| 3500/500 (M1U) | ||

| 4000/200 | Not Available |

|

| 4000/350 | Not Available |

|

| 4000/400 | Available Upon Special Request |

|

| 4000/500 | Available Upon Special Request |

Passenger - Two Car - Without Counterweight Safety

- SS = Single Side Opening

- CO = Center Opening

- Note: Counterweight safeties are required for buildings with occupied space beneath the elevator pit.

| Capacity (lbs.) / Speed (fpm) | Front Door Type | Front / Rear Door Type |

|---|---|---|

| 2000/200 | Not Available |

|

| 2000/350 | Not Available |

|

| 2500/200 | Not Available |

|

| 2000/350 | Not Available |

|

| 2000/400 (M1U) | Not Available |

|

| 2000/500 (M1U) | Not Available |

|

| 3000/200 | Not Available |

|

| 3000/350 | Not Available |

|

| 3000/400 (M1U) | Not Available |

|

| 3000/500 (M1U) | Not Available |

|

| 3500/200 | ||

| 3500/350 | ||

| 3500/400 (M1U) | ||

| 3500/500 (M1U) | ||

| 4000/200 | Not Available |

|

| 4000/350 | Not Available |

Passenger - Two Car - With Counterweight Safety

- SS = Single Side Opening

- CO = Center Opening

- Note: Counterweight safeties are required for buildings with occupied space beneath the elevator pit.

| Capacity (lbs.) / Speed (fpm) | Front Door Type | Front / Rear Door Type |

|---|---|---|

| 2000/200 | Not Available |

|

| 2000/350 | Not Available |

|

| 2500/200 | Not Available |

|

| 2500/350 | Not Available |

|

| 2500/400 (M1U) | Not Available |

|

| 2500/500 (M1U) | Not Available |

|

| 3000/200 | Not Available |

|

| 3000/350 | Not Available |

|

| 3000/400 (M1U) | Not Available |

|

| 3000/500 (M1U) | Not Available |

|

| 3500/200 | ||

| 3500/350 | ||

| 3500/400 (M1U) | ||

| 3500/500 (M1U) | ||

| 4000/200 | Not Available |

|

| 4000/350 | Not Available |

Service - One Car - Without Counterweight Safety

- 2S = Two Speed Side Opening

- Note: Counterweight safeties are required for buildings with occupied space beneath the elevator pit.

| Capacity (lbs.) / Speed (fpm) | Front Door Type | Front / Rear Door Type |

|---|---|---|

| 4000/200 | Not Available |

|

| 4000/350 | Not Available |

|

| 4500/200 | ||

| 4500/350 | ||

| 5000/200 | ||

| 5000/350 |

Service - One Car - With Counterweight Safety

- 2S = Two Speed Side Opening

- Note: Counterweight safeties are required for buildings with occupied space beneath the elevator pit.

| Capacity (lbs.) / Speed (fpm) | Front Door Type | Front / Rear Door Type |

|---|---|---|

| 4000/200 | Not Available |

|

| 4000/350 | Not Available |

|

| 4500/200 | ||

| 4500/350 | ||

| 5000/200 | ||

| 5000/350 |

Service - Two Car - Without Counterweight Safety

- 2S = Two Speed Side Opening

- Note: Counterweight safeties are required for buildings with occupied space beneath the elevator pit.

| Capacity (lbs.) / Speed (fpm) | Front Door Type | Front / Rear Door Type |

|---|---|---|

| 4000/200 | Not Available |

|

| 4000/350 | Not Available |

|

| 4500/200 | ||

| 4500/350 | ||

| 5000/200 | ||

| 5000/350 |

Service - Two Car - With Counterweight Safety

- 2S = Two Speed Side Opening

- Note: Counterweight safeties are required for buildings with occupied space beneath the elevator pit.

| Capacity (lbs.) / Speed (fpm) | Front Door Type | Front / Rear Door Type |

|---|---|---|

| 4000/200 | Not Available |

|

| 4000/350 | Not Available |

|

| 4500/200 | ||

| 4500/350 | ||

| 5000/200 | ||

| 5000/350 |